As pandemic recovery begins, the transport industry will have a new set of challenges to face. These supply chain changes are no longer all about furloughed employees, managing blended services, and meeting product demand for panicked consumers.

While supply chain leaders showed resiliency over the last year, they will need to continue to find solutions to changing demands. There remain areas within the industry that will be more affected than others as the world begins to reopen. Companies must prepare for these changes today.

Staffing Challenges

Despite increased demand from consumers and shifting buying patterns, the global economy suffered through a year of cost-cutting measures. Factory closures and in-house workers were furloughed due to the pandemic.

Increased consumer demand will extend the demand for new hires and boosts in staffing in both warehouse and transport roles. Additional road freight routes that managers cut due to staffing issues have returned to lessen the burden on transport providers. Staffing challenges will arise around onboarding fresh employees hired to handle an overburdened industry.

Flexibility Matters

The Covid-19 crisis laid bare problems within supply chain management. Specific industries came under the strain of changing spending habits and faced a massive shift to online shopping. At this point, consumers are still spending more on goods purchased online in person, and the industry has had to adapt.

Flexibility in the transport industry will continue post-Covid-19, with solutions necessary for working with swings in consumer behavior. Those swings have seen lower volumes during specific points of the year. They are forcing efficient and cost-effective solutions, no matter the cargo load.

Demand for cargo volumes will remain challenging to predict, with ocean shipping a particularly volatile piece of the puzzle. How companies adapt to those changes will be important moving forward.

A Need for Automation

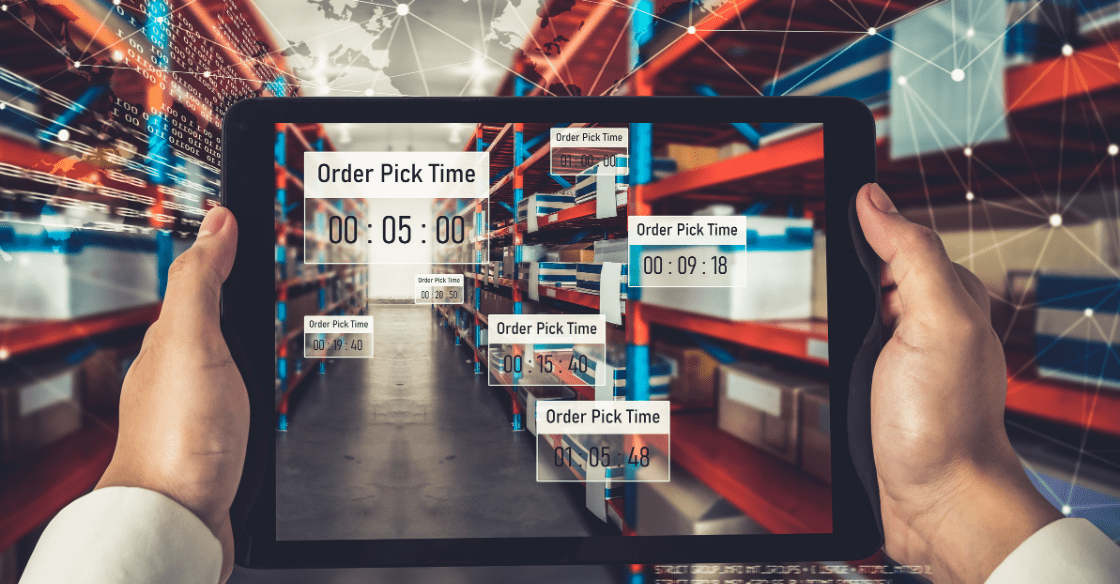

Companies that have worked to gather consumer data have been better able to inform transport scheduling and meet changing demands. Automation of specific processes allows companies to forecast where the market is going more accurately. In turn, they improve decision-making along the supply chain.

Digitization and machine learning will remain vital in reducing logistics costs, automating processes, and identifying inefficiencies in the supply chain.

The pandemic has also created a need to restrict face-to-face interaction whenever possible. More virtual interaction resulted in improvements in efficiency along the way.

Diversity in Supply Chains

One of the significant Covid-19 impacts on transport was that the global supply chain turned into a local one. Vendors looked to goods made domestically to address gaps in their supply chain networks. Gaps arose due to the pandemic, but also a trade war with China. China is a long-term supplier of many goods found in the United States.

Companies had to diversify suppliers, a trend that will likely continue as Covid-19 pandemic recovery continues. It has proven wise for companies to expand their resources. Especially when one production line is affected by political pressures, global health emergencies, or other unforeseen circumstances. Consolidation has proven to be dangerous.

Companies will also look to diversify in how they transport goods and raw materials. Gather quotes for shipping by sea, air, or road freight. The traditional rules don’t always apply in a volatile marketplace.

Logistics and Cost Concerns

Shipping costs only continue to rise as consumer behavior outpaces what the industry is able to handle in this moment. Those looking to export overseas are finding that costs have dramatically increased. On top of that, limitations on volume and shipping constraints have been implemented.

Those challenges will likely remain until shipping disruptions settle and consumer behavior returns to a semblance of pre-pandemic spending. The availability of one shipping mode over another may determine how companies adapt in response to supply chain changes. Pandemic recovery will also vary by industry, proving yet again how important flexibility is across transportation.

Quality Control

COVID-19 and commercial transport has led to delayed shipments, extended into weeks, leading to distrust in the industry. Consumers have faced a decrease in quality.

Quality control on the ground level is affected by global supply chains and the delays are cause for concern. Support in navigating these challenges will become an important investment as the economy recovers in real-time.

A Focus on the Future

Supply chain planning has been tested over the course of the last year. While we wait for customer demand to return to normal levels, continue keeping up with swings in the transport industry.

A third-party logistics provider like HLOG ensures your shipping and transportation decisions are informed. Contact us today to learn more about how we can support you conduct business efficiently and cost-effectively today.